RETAPP – ENABLING THE VALUE-CHAIN FROM WOOD TO PLASTIC PACKAGING

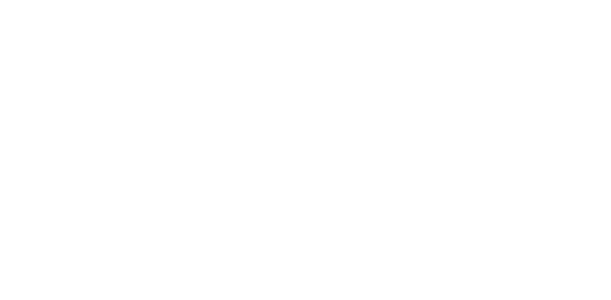

The main objectives of the ReTAPP project are to demonstrate the production of fructose from wood-based feedstock and to prepare the whole value chain for the market introduction of PEF resin using this fructose. The processes will be optimised and demonstrated by the three consortium partners: SEKAB, a technology provider for the wood-to-sugars technology; Avantium, world leader in the production of PEF; and MetGen, which provides the enzymes to make the processes more economically and environmentally sustainable.

The main objectives of the ReTAPP project are to demonstrate the production of fructose from wood-based feedstock and to prepare the whole value chain for the market introduction of PEF resin using this fructose. The processes will be optimised and demonstrated by the three consortium partners: SEKAB, a technology provider for the wood-to-sugars technology; Avantium, world leader in the production of PEF; and MetGen, which provides the enzymes to make the processes more economically and environmentally sustainable.

ReTAPP consortium

MetGen Oy (Coordinator) is an innovative Finnish SME which designs and markets novel MetZyme® enzymatic solutions for the most challenging of industrial conditions enabling novel applications and combinations with other enzymes to meet our customer specific need. MetGen has developed a very cost-effective and streamlined development and manufacturing process of industrial enzymes that can easily be adopted to any required changes and parameters in industrial production. In ReTAPP, MetGen will develop and provide other consortium partners tailored industrial enzymes and enzymatic solutions for their existing process, both for the recovery of reducing sugars from woody biomass by enzymatic hydrolysis and bioconversion of Glucose to Fructose. MetGen has a technology platform – ENZINE® (TRL 8) – in place to develop novel industrial enzymes and further tailored existing solutions for specific needs in fast, flexible and adaptable manner.

MetGen Oy (Coordinator) is an innovative Finnish SME which designs and markets novel MetZyme® enzymatic solutions for the most challenging of industrial conditions enabling novel applications and combinations with other enzymes to meet our customer specific need. MetGen has developed a very cost-effective and streamlined development and manufacturing process of industrial enzymes that can easily be adopted to any required changes and parameters in industrial production. In ReTAPP, MetGen will develop and provide other consortium partners tailored industrial enzymes and enzymatic solutions for their existing process, both for the recovery of reducing sugars from woody biomass by enzymatic hydrolysis and bioconversion of Glucose to Fructose. MetGen has a technology platform – ENZINE® (TRL 8) – in place to develop novel industrial enzymes and further tailored existing solutions for specific needs in fast, flexible and adaptable manner.

SEKAB E-Technology is one of Europe’s leading ethanol manufacturers. We convert and refine ethanol to biofuels and chemicals and develop new cellulose based biorefinery technology. We believe that sustainability is about resources that last now and in the future. The company is a part of the SEKAB group and has the head quarter and main production in Örnsköldsvik at the Baltic Sea. SEKAB has long experience of advanced research regarding development and scale-up of process technology. SEKAB has over 10 years of experience of demo plant tests and operations running in 24/7. Experience and data from pre-engineering of softwood based ethanol plants in Sweden. In ReTAPP, SEKAB will offer its advanced pre-treatment and hydrolysis platform, CelluAPP® for an efficient and sustainable process to depolymerise cellulose materials, such as forest and agricultural residues, to sugars.

SEKAB E-Technology is one of Europe’s leading ethanol manufacturers. We convert and refine ethanol to biofuels and chemicals and develop new cellulose based biorefinery technology. We believe that sustainability is about resources that last now and in the future. The company is a part of the SEKAB group and has the head quarter and main production in Örnsköldsvik at the Baltic Sea. SEKAB has long experience of advanced research regarding development and scale-up of process technology. SEKAB has over 10 years of experience of demo plant tests and operations running in 24/7. Experience and data from pre-engineering of softwood based ethanol plants in Sweden. In ReTAPP, SEKAB will offer its advanced pre-treatment and hydrolysis platform, CelluAPP® for an efficient and sustainable process to depolymerise cellulose materials, such as forest and agricultural residues, to sugars.

Avantium Chemicals BV was founded in 2000 as a spin-off from Royal Dutch Shell, specialised in high-throughput research in the fields of catalyst testing development. This part of the company now focuses solely on catalysis research, providing expertise and high-tech equipment to the chemical industry. Since 2005 the company has been applying its advanced catalysis research expertise in the field of biomass conversion in order to develop building blocks for a biobased economy. The first of these projects has led to the development of the YXY process, which deals with the conversion of sugars into furanics. From these furanics polyethylene furanoate, a replacement for PET (polyethylene terephtalate) with considerably improved properties, can be produced. This process is now on its way to commercialisation due to the formation of Synvina, a joint venture together with BASF, in October 2016.. The success of the YXY process has spawned a number of new projects in the field of renewables, including ReTAPP, leading to processes for 2nd generation biomass conversion into sugars and other useful base chemicals. Avantium is continually exploring novel ideas for biobased replacements of current fossil-based products and processes, as well as the development of applications for side-streams generated by different biomass feedstocks.

Avantium Chemicals BV was founded in 2000 as a spin-off from Royal Dutch Shell, specialised in high-throughput research in the fields of catalyst testing development. This part of the company now focuses solely on catalysis research, providing expertise and high-tech equipment to the chemical industry. Since 2005 the company has been applying its advanced catalysis research expertise in the field of biomass conversion in order to develop building blocks for a biobased economy. The first of these projects has led to the development of the YXY process, which deals with the conversion of sugars into furanics. From these furanics polyethylene furanoate, a replacement for PET (polyethylene terephtalate) with considerably improved properties, can be produced. This process is now on its way to commercialisation due to the formation of Synvina, a joint venture together with BASF, in October 2016.. The success of the YXY process has spawned a number of new projects in the field of renewables, including ReTAPP, leading to processes for 2nd generation biomass conversion into sugars and other useful base chemicals. Avantium is continually exploring novel ideas for biobased replacements of current fossil-based products and processes, as well as the development of applications for side-streams generated by different biomass feedstocks.

ReTAPP value-chain

Project Summary

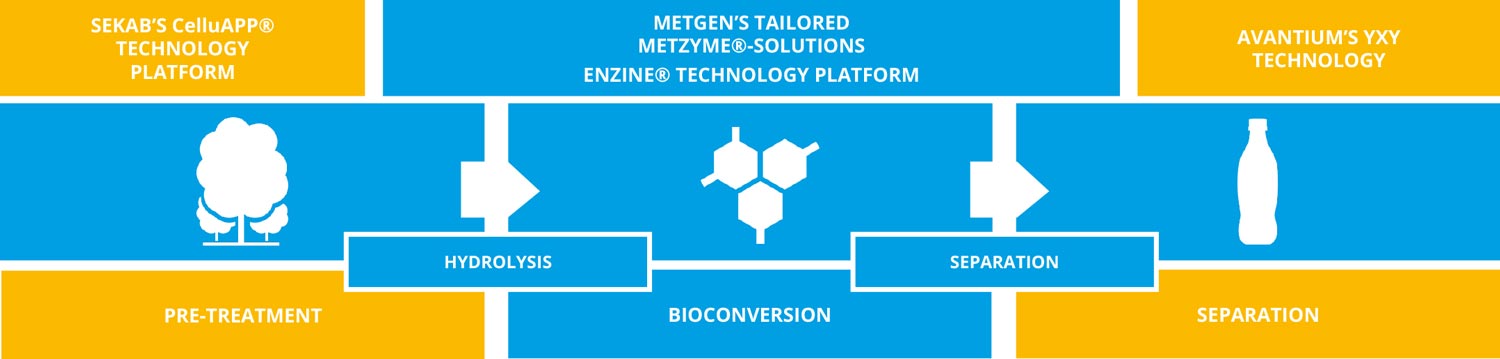

The aim of the ReTAPP (ReThink All Plastic Packaging) project is to produce fructose from wood (hardwood and softwood): a conversion for which has never been commercialised before. With current methods, hardwood is very hard to fractionate to sugars. In addition, most of the sugars in hardwood are glucose and xylose, which need to be transformed to fructose. The ReTAPP project will make this process technologically and economically feasible with the help of enzymatic solutions. The mixture of fructose and glucose resulting from the enzymatic isomerisation of the wood-based glucose requires workup in order to obtain high fructose syrup (HFS). The fructose thus produced can then be converted into RMF (alkoxymethylfurfural) and 5-HMF (5-(Hydroxymethyl)furfural), to be used to produce PEF (polyethylene furanoate) – a bio-based alternative to replace the PET (polyethylene terephthalate) plastics, with enhanced barrier, thermal and mechanical properties over existing packaging materials.

The illustration of the ReTAPP project concept.

In the ReTAPP project, the processes will be optimized and piloted by the three partners: SEKAB, a technology

provider for the wood-to-sugars technology; Avantium, world leader in the production of PEF; and MetGen, the provider of the enzymes to make the processes more economically and environmentally sustainable.

Thus, the main objectives of the project can be summarized to demonstrate the production of fructose from wood and prepare the whole value chain for the market introduction of this wood-based fructose, it workup and conversion into RMF. This includes:

- Verify that sugars from depolymerised hardwood and softwood are suitable for the conversion into fructose and subsequently into polymers: With the yield and other process performance obtained, calculations will be carried out for commercial scale production, regarding investment and operation costs.

- Demonstrate an increase in the reducible sugar yield by 10 % in the hydrolysis phase.

- Demonstrate a reduction of 10 % in energy use throughout all the wood processing phases.

- Demonstrate a reduction in the fructose price of more than 18 %, in comparison to the price of food-based fructose on the markets today (0.5€/kg).

- Do three pilot-scale production campaigns of wood-based fructose, with yields of over 80 %.

- Demonstrate the process from wood-based fructose to polymers, using the fructose produced by MetGen from glucose provided by SEKAB, including separation of fructose from glucose and the conversion of the resulting HFS into RMF using Avantium’s continuous flow technology. This RMF can be used to produce PEF using YXY technology, which is being commercialised by Synvina, a joint venture between BASF and Avantium.

As a result of a successful execution of this project, MetGen will have several novel enzymatic solutions to market and supply to hardwood-to-chemicals processes; SEKAB a proprietary wood-to-sugars process technology that can be licenced out; and Avantium a new, non-food based renewable source of raw material.

Avantium estimates the yearly market for fructose for biobased chemicals to be in the order of 1.5 million tons by 2021. By the beginning of the next decade, Avantium’s Flagship plant, now vested in the Avantium/BASF JV named Synvina, will be on stream making a rapid increase of the production of wood-based fructose possible reaching 10000 ton / year by the end of that decade. Already at less than 10% market capture of the enzymatic solutions for fructose production by 2021, the sales of MetGen enzymes for this application are estimated to exceed 10 M€, while another 10M€ could be saved in fructose production costs.

Achievements

- MetGen has developed novel glucose isomerase capable of efficiently converting wood-based glucose into fructose even in crude hydrolysates (with up to 25% xylose), showing much better results than the enzymes used in commercial fructose production.

- MetGen has successfully scaled up the production of glucose isomerase to an industrial scale (50 m3).

- MetGen has achieved 54% glucose to fructose conversion in lab-scale and 45% in pilot-scale.

- MetGen glucose isomerase has been demonstrated to be suitable in continuous column process conditions at 70-80 °C by remaining active in the studied process conditions significantly longer (6 days vs. 12 days) and performing more efficiently than commercial available solutions.

- The glucose to fructose conversion with MetGen’s MetZyme® PURECO™ has been successfully demonstrated in demo-scale (6 m3).

- SEKAB has demonstrated the production of cellulosic sugars from wood-based feedstock with over 80% glucose yield from cellulose.

- SEKAB has developed and demonstrated a process for the separation of xylose rich liquid streams from the solid cellulose stream in the Biorefinery Demo Plant, which improves the conditions for enzymatic hydrolysis.

- SEKAB has tested and verified the CelluAPP® conversion process to handle pulp chips and even wood chips of larger size and still maintain the process yields. That indicates less need for energy consuming mechanical treatment before the CelluAPP® conversion process.

- SEKAB has produced glucose and xylose both from hardwood and softwood during the project and already produced a total sugar amount of more than 2000 kg wood-based sugars.

- MetGen has demonstrated that the addition of the MetZyme® SUNO™ booster to hydrolysis solutions used in SEKAB

- CelluAPP® process increases sugar yield by 25%-30% and decreases the enzyme dosage by 50%.

- MetZyme® SUNO™ solutions have been demonstrated to perform equal to commerical enzyme cocktails in SEKAB CelluAPP® process in Biorefinery Demo Plant.

- Avantium is working on novel glucose/fructose separation technology to be able to make a feed high in fructose from the batches provided by MetGen. This technology should significantly reduce costs as well as lower the environmental burden of glucose/fructose separations.

- Avantium has developed and is currently in the final stages of building and commissioning novel parallel flow equipment to carry out experiments with C5 xylose/xylulose as well as fructose enriched C6 sugar feeds to prove the suitability of SEKAB and MetGen solutions to produce fructose from hardwood for the production of FDCA and PEF.

- High level techno-economic study shows that an economically sound business case is feasible if established using the assumptions of the ReTAPP project.

Partner websites:

MetGen: www.metgen.com

SEKAB: www.sekab.com

Avantium: www.avantium.com

Selected conferences presentations:

MetGen: “Highly Effective Enzyme Solutions for Cellulosic Biomass Conversion” at Creating Bioeconomic Growth – Industrial Biotechnology Business Seminar, 2 June, 2016, Aalto Design Factory, Espoo, Finland

MetGen: “Enzymatic challenges in modern biorefineries” at Lignofuels 2016 Conference, 20-21 January 2016, Munich, Germany

Conferences attended to promote ReTAPP:

255th ACS National Meeting & Expo 2018, March 18-22, 2018, New Orleans, Louisiana, USA

Advanced Bioeconomy Leadership Conference (ABLC) 2018, Washington, February 28-Mar. 2 2018

10th World Congress of Chemical Engineering, 1-5 October 2017, Barcelona, Spain

Enzyme Engineering XXIV Conference, 24-28 September 2017, Toulouse, France

Brightlands Rolduc Polymer Conference 2017, 10-13 September 2017, Kerkrade, The Netherlands

EuroNanoForum 2017, EuroNanoForum 2017, 21-23 June 2017, , Valletta, Malta

European Biomass conference & Exhibition (EUBCE 2017), 12-15 of June 2017, Stockholm, Sweden

Skogskemi 2.0, 16 May 2017, Gothenburg, Sweden

International Conference on Bio-based Materials, 10-11 May 2017, Cologne, Germany

Advanced Bioeconomy Leadership Conference (ABLC) 2017, 1-3 March 2017, Washington, DC

TAPPI’s 2016 International Bioenergy and Bioproducts Conference (IBBC) 28–30 September, 2016, Jacksonville, FL, USA.

International Wood Biorefining (IWB) Week 2016, 24-26 May, 2106, Stockholm, Sweden.

Creating Bioeconomic Growth – Industrial Biotechnology Business Seminar, 2 June, 2016, Aalto Design Factory, Espoo, Finland

OxiZymes 2016, 8th European Meeting on OxiZymes, 3-6 July 2016, Wageningen, The Netherlands

Lignobiotech IV Symposium, 4th Symposium on Biotechnology applied to Lignocelluloses, 19-22 June, 2016, Madrid, Spain

World Bio Markets (WBM) 2016, 14-17 March 2016, Amsterdam, The Netherlands

RISI European 2016, 18th Annual RISI European Conference, 29 February – 02 March 2016, Berlin, Germany

Lignofuels 2016 Conference, 20-21 January 2016, Munich, Germany

Other relevant EU H2020 projects:

BIOrescue – Enchanced bioconversion of agricultural residues through cascading use

ButaNexT – Next generation biobutanol

FALCON – Fuel and chemicals from lignin through enzymatic and chemical conversion

BioCatPolymers – Sustainable and efficient bio-chemical catalytic cascade conversion of residual biomass to high quality biopolymers biopolymers

BIO-based products from FORestry via Economically Viable European Routes (BIOFOREVER).

Other interesting links :

Avantium – Renewable Chemistry – The Only Way is Up (video)

Matti Heikkilä, CTO of MetGen: A clear path ahead of the bioeconomy– Expert opinion in European Biotechnology Life Science and Industry Magazine, 2017

Contact Us

Petri Ihalainen, PhD, Docent

EU project manager

Tel: +358 40 553 1458

Email: petri.ihalainen@metgen.com

LinkedIn

Skype: petri_ihalainen

Matti Heikkilä

CTO

Tel: +358 40 354 0701

Email: matti.heikkila@metgen.com

LinkedIn

Skype: mwheikkila

The ReTAPP project has received funding from the European Union Horizon 2020 Research and Innovation Programme under grant agreement no 691414.

Metgen_A0_Poster

Metgen_A0_Poster_ReTAPP